-

SKIPPING ROPE BAG

Qty: 13.00 €

SKIPPING ROPE BAG

Qty: 13.00 € -

BATTLE ROPE 12 METERS

Qty: 159.00 €

BATTLE ROPE 12 METERS

Qty: 159.00 € -

FAST SKIPPING ROPE

Qty: 214.00 €

FAST SKIPPING ROPE

Qty: 214.00 € -

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 €

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 € -

WEIGHTED SKIPPING ROPE

Qty: 118.50 €

WEIGHTED SKIPPING ROPE

Qty: 118.50 € -

WOODEN PLYO BOX

Qty: 195.00 €

WOODEN PLYO BOX

Qty: 195.00 € -

20KG PLATE WEIGHT VEST

Qty: 295.00 €

20KG PLATE WEIGHT VEST

Qty: 295.00 € -

WEIGHT BLOCK SET

Qty: 115.20 €

WEIGHT BLOCK SET

Qty: 115.20 € -

ELITE SKIPPING ROPE

Qty: 123.50 €

ELITE SKIPPING ROPE

Qty: 123.50 € -

AB MAT

Qty: 110.50 €

AB MAT

Qty: 110.50 € -

30KG BLOCK WEIGHT VEST

Qty: 195.00 €

30KG BLOCK WEIGHT VEST

Qty: 195.00 € -

PARALLETTES

Qty: 144.00 €

PARALLETTES

Qty: 144.00 € -

RINGS

Qty: 138.00 €

RINGS

Qty: 138.00 € -

ELITE YOKE 2.0

Qty: 11,270.00 €

ELITE YOKE 2.0

Qty: 11,270.00 € -

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 €

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 € -

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 €

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 € -

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 €

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 € -

TECHNIQUE BARBELL

Qty: 1112.00 €

TECHNIQUE BARBELL

Qty: 1112.00 € -

SPRING COLLAR

Qty: 12.40 €

SPRING COLLAR

Qty: 12.40 € -

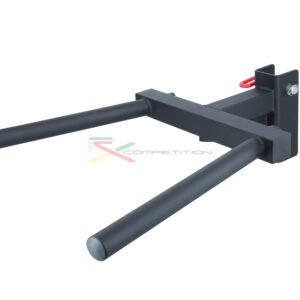

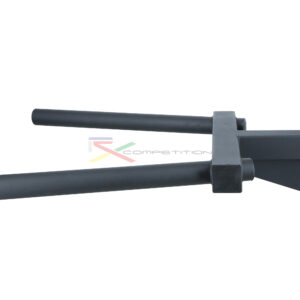

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 €

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 € -

ELITE MONKEY BAR 1800

Qty: 1107.60 €

ELITE MONKEY BAR 1800

Qty: 1107.60 € -

ELITE MONKEY BAR 1100

Qty: 1104.60 €

ELITE MONKEY BAR 1100

Qty: 1104.60 €

-

SKIPPING ROPE BAG

Qty: 13.00 €

SKIPPING ROPE BAG

Qty: 13.00 € -

BATTLE ROPE 12 METERS

Qty: 159.00 €

BATTLE ROPE 12 METERS

Qty: 159.00 € -

FAST SKIPPING ROPE

Qty: 214.00 €

FAST SKIPPING ROPE

Qty: 214.00 € -

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 €

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 € -

WEIGHTED SKIPPING ROPE

Qty: 118.50 €

WEIGHTED SKIPPING ROPE

Qty: 118.50 € -

WOODEN PLYO BOX

Qty: 195.00 €

WOODEN PLYO BOX

Qty: 195.00 € -

20KG PLATE WEIGHT VEST

Qty: 295.00 €

20KG PLATE WEIGHT VEST

Qty: 295.00 € -

WEIGHT BLOCK SET

Qty: 115.20 €

WEIGHT BLOCK SET

Qty: 115.20 € -

ELITE SKIPPING ROPE

Qty: 123.50 €

ELITE SKIPPING ROPE

Qty: 123.50 € -

AB MAT

Qty: 110.50 €

AB MAT

Qty: 110.50 € -

30KG BLOCK WEIGHT VEST

Qty: 195.00 €

30KG BLOCK WEIGHT VEST

Qty: 195.00 € -

PARALLETTES

Qty: 144.00 €

PARALLETTES

Qty: 144.00 € -

RINGS

Qty: 138.00 €

RINGS

Qty: 138.00 € -

ELITE YOKE 2.0

Qty: 11,270.00 €

ELITE YOKE 2.0

Qty: 11,270.00 € -

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 €

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 € -

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 €

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 € -

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 €

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 € -

TECHNIQUE BARBELL

Qty: 1112.00 €

TECHNIQUE BARBELL

Qty: 1112.00 € -

SPRING COLLAR

Qty: 12.40 €

SPRING COLLAR

Qty: 12.40 € -

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 €

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 € -

ELITE MONKEY BAR 1800

Qty: 1107.60 €

ELITE MONKEY BAR 1800

Qty: 1107.60 € -

ELITE MONKEY BAR 1100

Qty: 1104.60 €

ELITE MONKEY BAR 1100

Qty: 1104.60 €

-

SKIPPING ROPE BAG

Qty: 13.00 €

SKIPPING ROPE BAG

Qty: 13.00 € -

BATTLE ROPE 12 METERS

Qty: 159.00 €

BATTLE ROPE 12 METERS

Qty: 159.00 € -

FAST SKIPPING ROPE

Qty: 214.00 €

FAST SKIPPING ROPE

Qty: 214.00 € -

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 €

6 MTS POLYPROPYLENE CLIMB ROPE

Qty: 167.75 € -

WEIGHTED SKIPPING ROPE

Qty: 118.50 €

WEIGHTED SKIPPING ROPE

Qty: 118.50 € -

WOODEN PLYO BOX

Qty: 195.00 €

WOODEN PLYO BOX

Qty: 195.00 € -

20KG PLATE WEIGHT VEST

Qty: 295.00 €

20KG PLATE WEIGHT VEST

Qty: 295.00 € -

WEIGHT BLOCK SET

Qty: 115.20 €

WEIGHT BLOCK SET

Qty: 115.20 € -

ELITE SKIPPING ROPE

Qty: 123.50 €

ELITE SKIPPING ROPE

Qty: 123.50 € -

AB MAT

Qty: 110.50 €

AB MAT

Qty: 110.50 € -

30KG BLOCK WEIGHT VEST

Qty: 195.00 €

30KG BLOCK WEIGHT VEST

Qty: 195.00 € -

PARALLETTES

Qty: 144.00 €

PARALLETTES

Qty: 144.00 € -

RINGS

Qty: 138.00 €

RINGS

Qty: 138.00 € -

ELITE YOKE 2.0

Qty: 11,270.00 €

ELITE YOKE 2.0

Qty: 11,270.00 € -

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 €

WOMEN ELITE RUSSIAN BARBELL

Qty: 1490.00 € -

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 €

MEN ELITE WEIGHTLIFTING BARBELL

Qty: 1272.20 € -

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 €

WOMEN REGULAR HYBRID BARBELL

Qty: 1178.90 € -

TECHNIQUE BARBELL

Qty: 1112.00 €

TECHNIQUE BARBELL

Qty: 1112.00 € -

SPRING COLLAR

Qty: 12.40 €

SPRING COLLAR

Qty: 12.40 € -

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 €

ELITE PLATE STORAGE CHANNEL 26 MM

Qty: 150.50 € -

ELITE MONKEY BAR 1800

Qty: 1107.60 €

ELITE MONKEY BAR 1800

Qty: 1107.60 € -

ELITE MONKEY BAR 1100

Qty: 1104.60 €

ELITE MONKEY BAR 1100

Qty: 1104.60 €

POWER RACKS

Home » RIGS & RACKS » ELITE » POWER RACKS

POWER RACKS

The Power Rack, or Power Cage, is the most common used structure for strength training, power development, balance, and coordination of movements.

It is a structure supported by four upright pillars, usually made of steel, interconnected by different crossbars designs with different functionalities.

The Power Rack purpose is to provide increased safety and convenience in strength training, allowing to practice training exercises such as squats or bench presses and enabling the starting position to be set at a specific pre-selected height.

In addition to enhancing safety and convenience in exercise execution, Power Racks also offer great versatility by providing a wide range of compatible accessories for various purposes.

It is crucial to consider certain technical, structural, and design details when choosing a good Power Rack to ensure a minimum level of quality and safety:

- Steel material: It is important that the steel used is high-quality carbon steel (or stainless steel for outdoor use) sourced from certified foundries. This guarantees a homogeneous and solid structure without breakage or cracking risk.

- Height: Power Racks should have a minimum height of 2.10 meters up to 2.70 meters to allow for unrestricted movement.

- Upright Dimensions: High-quality Power Racks that can offer a performance guarantee should be composed of at least 60 x 60 mm square laminated tubing with a minimum thickness of 2 mm to ensure strength, safety, and stability in the structure.

- Upright Numbering: It is essential for all four frame upright pillars to be numbered on all their holes for allowing a quick support height adjustment when changing training exercises. High-end Power Racks offer a 50 mm hole spacing, and each hole is individually numbered. In such cases, the holes and numbers are laser-cut.

- Screws: The material and metric size of the screws also play a role in determining the quality and rigidity of the frame. The bigger the metric size of the screws, the more solid and safety the whole structure will be.

- Accessories range: A good Power Rack should include a wide accessories range to provide maximum versatility and training possibilities.

Our Elite category structures are manufactured using square structural 80 x 80 x 4 mm S235 steel grade profiles with 10 mm thickness assembling sheet bases. All these frames are assembled throw DIN-931 AISI-304 stainless steel M-20 sized bolts with DIN-985 nylon lock AISI-304 stainless steel M-20 sized nuts.

Currently, no other manufacturer offers this quality level in their frames.